CRANE Temper

CRANE Temper represents a groundbreaking advancement in refrigeration technology, offering exceptional advantages for a wide range of applications. This ready-mixed, non-toxic organic salt solution excels in biodegradability, low viscosity, high specific heat capacity, and exceptional thermal conductivity, setting a new standard for environmentally friendly heat transfer fluids. Ideal for industrial and food refrigeration, CRANE Temper is available in seven versions, accommodating temperatures from -10°C to -60°C.

With exceptional thermal properties and low viscosity, CRANE Temper provides a uniquely efficient system, maximizing performance and reducing energy costs. Its effective corrosion inhibitor package ensures longevity and reliability of your refrigeration system, reducing maintenance costs and preventing downtime. CRANE Temper maintains its thermal properties over time, guaranteeing consistent performance and lowering operational costs. Backed by decades of practical application and continuous improvement, its superior thermal properties often result in a higher evaporator temperature compared to glycols, enhancing efficiency while minimizing environmental impact.

Choosing CRANE Temper means investing in a reliable product backed with comprehensive technical support to ensure your cooling systems remain efficient, reliable, and sustainable.

Key advantages at a glance

- Nontoxic

- Low viscosity

- High thermal conductivity

- Low freezing points

- Chemically stable

- Reduced installation and energy costs

- Readily biodegradable

- Adapted for the food industry

- Advanced inhibitor technology

- Personalised technical support

Areas of use, industries and installations

CRANE Temper can be used wherever a liquid Heat Transfer Fluid is required in indirect cooling, stationary or mobile installations.

Food industry

Food processing is a vital part of the food industry; an unbroken cold chain is necessary to keep the quality of the goods. With an indirect cooling system with i.e. Ammonia (NH3) as a refrigerant and CRANE Temper as heat transfer fluid, the industry has a very powerful and environmentally adapted heat transfer fluids used in many secondary refrigeration systems.

When comparing CRANE Temper with Propylene glycol, CRANE Temper has significantly better thermal properties, resulting in a reduced energy consumption and offer energy efficient system. CRANE Temper is non-toxic and registered in NSF Nonfood Compounds Program.

Distribution & logistics centres

Refrigeration is a key factor to ensure high quality in distribution of fresh food. Indirect systems with CRANE Temper provide distribution- and logistics centers all over the world with stable and efficient secondary cooling systems.

By choosing CRANE Temper with its low viscosity, energy consumption is significantly reduced. In addition, a system with secondary loops can easily be extended/adapted without affecting ongoing cooling activities, by just adding an additional loop.

Defrosting of CO2 air coolers

The defrosting phase of a refrigeration process is always the most sensitive period, when the goods are subjected to considerably higher temperatures than for which they were intended.

When humidity enters a cold room, the CO2 air coolers need to be defrosted regularly. Normally, this is done by electrical defrosting, which is very energy consuming. Evaporating the frost means adding humidity into the air and thereby increased and faster frost build-up and more defrosting cycles. Switching to brine defrosting with CRANE Temper enhances the efficiency of the defrosting process and offers a shorter payback period compared to electrical defrosting.

This approach utilizes waste heat from the condenser to heat the brine for defrosting the air coolers. This solution not only provides the cold storage facility with an energy-efficient system but also substantially reduces CO2 emissions and can be adapted in many other applications.

The implementation of a warm brine defrost system can reduce the frequency of defrost cycles by 50% and decrease the duration of each defrost cycle by up to 75%, from the initiation of defrosting until the system temperature returns to normal operating levels. When defrosting a freezer application with electrical rods you will evaporate the frost instead of melting it as with warm brine defrost. This prolongs the life span of the food compared to standard method.

Pharmaceutical industry

CRANE Temper is a revolutionary heat transfer fluid, used in the pharmaceutical industry due to its exceptional thermal properties at low temperatures together with being non-toxic and readily biodegradable. With its low viscosity and superior thermal conductivity, it ensures high efficiency and precise temperature control, essential for pharmaceutical manufacturing and storage.

CRANE Temper’s long-term stability guarantees consistent thermal performance, maintaining the integrity and quality of pharmaceutical products. Investing in CRANE Temper means choosing a proven, reliable solution that supports the stringent requirements of the pharmaceutical industry.

Powerplants

In energy plant applications, such as gas turbines, combined cycle power plants and other turbine systems, the bearings are cooled by oil, which needs a cooling system. In approximately 80% of all plants built around the world, an antifreeze is required in the cooling system. Excess heat is often used for anti-icing of incoming air for the gas turbine. Remaining heat is removed by outdoor fan coolers, which have a high risk of freezing due to ambient temperature.

CRANE Temper has, together with our customers, decades of experience and numerous successful references within this field. CRANE Temper’s thermal and environmental properties make it an excellent choice of heat transfer fluid when environmental standards and requirements needs to be taken into account.

Climate test centre

Climate test chambers are widely used in, for instance the automotive industry for low temperature testing of components such as engines, heating system, oils and more. These chambers are also performed in other industrial applications, like testing heat pumps and conducting aerothermal testing. When extreme temperature conditions are required (down to -55°C), CRANE Temper is an ideal product. It functions as an energy-efficient heat transfer fluid or antifreeze, making it ideal for applications in climate test centres or any setting where a cooling system and a fluid with a low freezing point are needed.

Fuel cell / hydrogen filling station

Using hydrogen as an energy source in various industries can significantly reduce global greenhouse gas emissions. For example, hydrogen fuel cells produce electricity by combining hydrogen with oxygen, and their only byproduct is water. Efficient cooling is crucial for hydrogen storage and refueling. To optimize refueling, hydrogen is cooled to around -33°C to -40°C before reaching the vehicle, which reduces its volume and speeds up the refueling process.

Incorporating CRANE Temper as a heat transfer fluid in an indirect cooling system at hydrogen fuel stations ensures low energy consumption and high efficiency. With its low viscosity, CRANE Temper offers a sustainable solution by minimizing energy use and operational costs. Additionally, CRANE Temper is biodegradable and remains stable over time, providing a long-term and environmentally friendly solution. As hydrogen vehicle production increases, CRANE Temper can help advance the industry toward a cleaner future.

Supermarkets

Supermarkets are the cornerstones in modern life and a high quality of refrigerated and frozen products is taken for granted in our everyday life. A secondary refrigeration system with CRANE Temper as heat transfer fluid will ensure high quality of the products and minimize the environmental footprint.

CRANE Temper is a non-toxic heat transfer fluid designed to meet the highest standards in energy efficiency and sustainable for any food application.

Physical Properties

| Unit | T-10 | T-15 | T-20 | T-30 | T-40 | T-55 | T-60 | |

|---|---|---|---|---|---|---|---|---|

| Density | kg/m³ | 1087 | 1120 | 1145 | 1186 | 1215 | 1246 | 1260 |

| Specific heat | kJ/kg • °C | 3,772 | 3,575 | 3,434 | 3,244 | 3,114 | 2,966 | 2,820 |

| Thermal conductivity | W/m • °C | 0,480 | 0,472 | 0,462 | 0,436 | 0,428 | 0,421 | 0,440 |

| Dynamic viscosity | mPa • s | 1,53 | 1,90 | 2,03 | 3,33 | 3,82 | 4,28 | 4,28 |

| Kinematic viscosity | mm²/s | 1,40 | 1,70 | 1,78 | 2,81 | 3,15 | 3,43 | 3,40 |

Thermal Properties Calculator

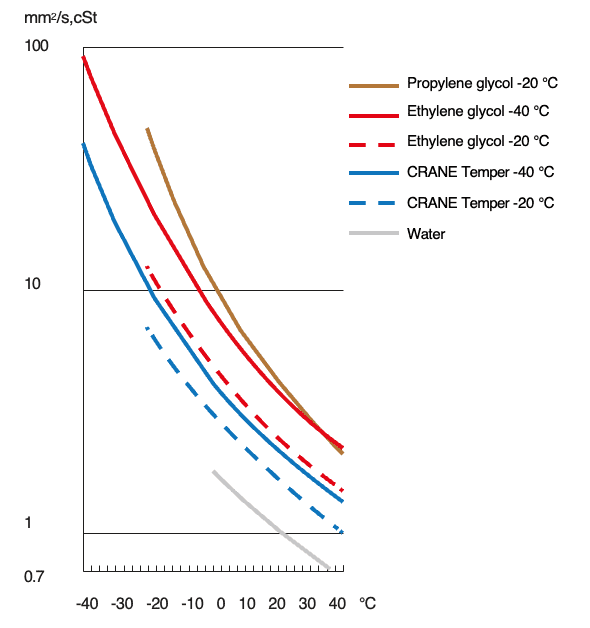

The main part of cooling and freezing is within food applications. MPG or 1,2-MonoPropylene Glycol is perhaps the most commonly used heat transfer fluid in those applications. Already at below -20°C the viscosity of MPG is very high and the energy demand increase significantly. Already @ -30°C, the viscosity gets too high for practical use in centrifugal pumps. A thumb rule is that at kinematic viscosity above 300 cSt, centrifugal pumps cannot be used. Other types of pumps are very expensive and inefficient. The calculations (Reynolds number, pressure drop and heat transfer coefficient) are made for circular tubes.

Performance

CRANE Temper’s excellent fluid properties in terms of viscosity, specific heat and thermal conductivity make it the ideal choice as Heat Transfer Fluid (HTF) at very low temperatures. The fluid properties not only enable users to use smaller pumps and heat exchangers but also significantly reduce total energy consumption. This applies especially at very low temperatures, as seen in the comparison between CRANE Temper and Glycol presented in the graph.

Kinematic Viscosity of Temper and Glycol

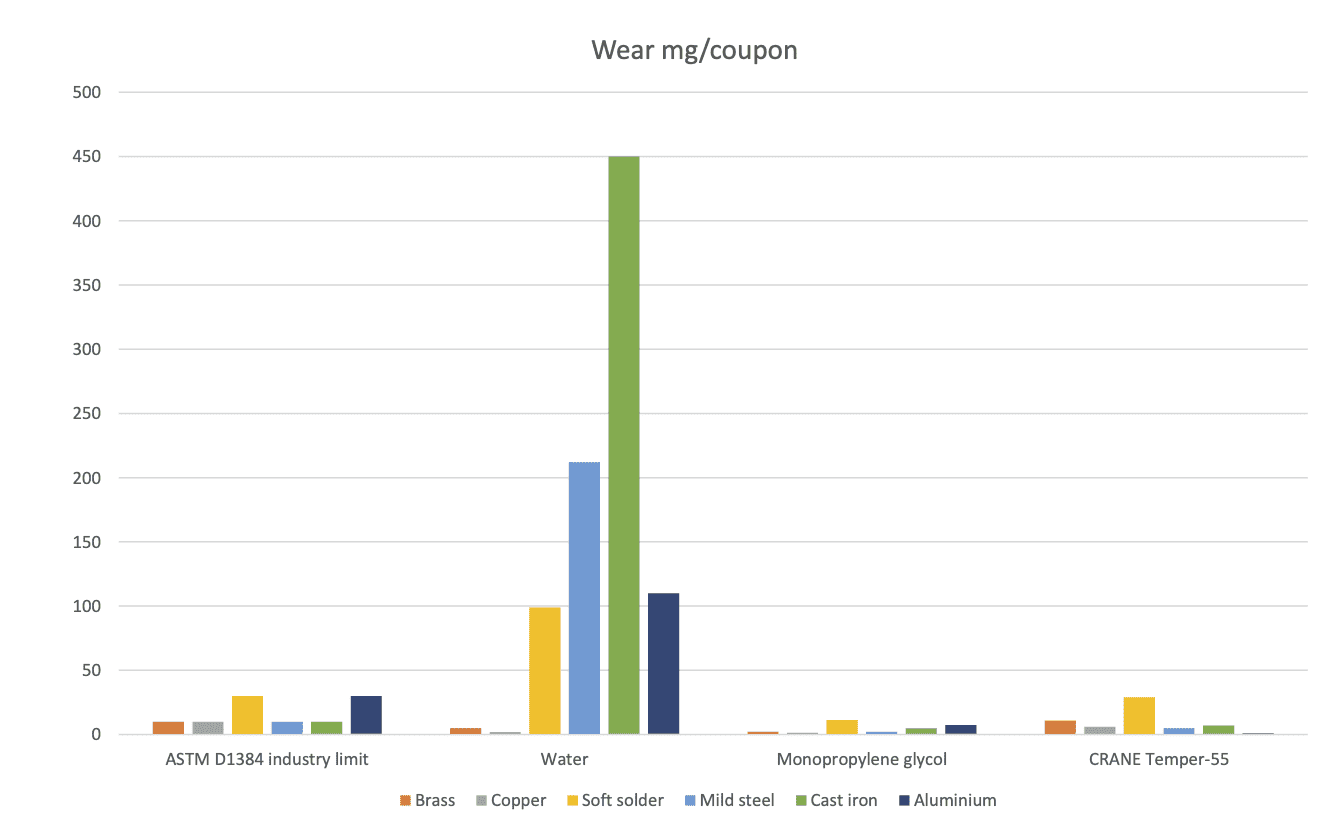

Corrosion Protection

CRANE Temper is a high-quality product based on potassium salts with an optimal concentration of corrosion inhibitors. The optimal corrosion package creates, and only when necessary, a local temporary and protective layer with a minimal (mono-molecular) thickness at the metal surface, which allows very good heat transfer. Together with your regular fluid status check-up (recommended once a year) the concentration of the corrosion inhibitor can be analysed to make sure it is at an acceptable level.

To quantify the corrosion protection efficiency, different corrosion tests are used. KRAHN Specialty Fluids has chosen the ASTM D1384 test, which is the most frequently used among heat transfer fluids. Figures in the table represent the change in weight before and after the test.

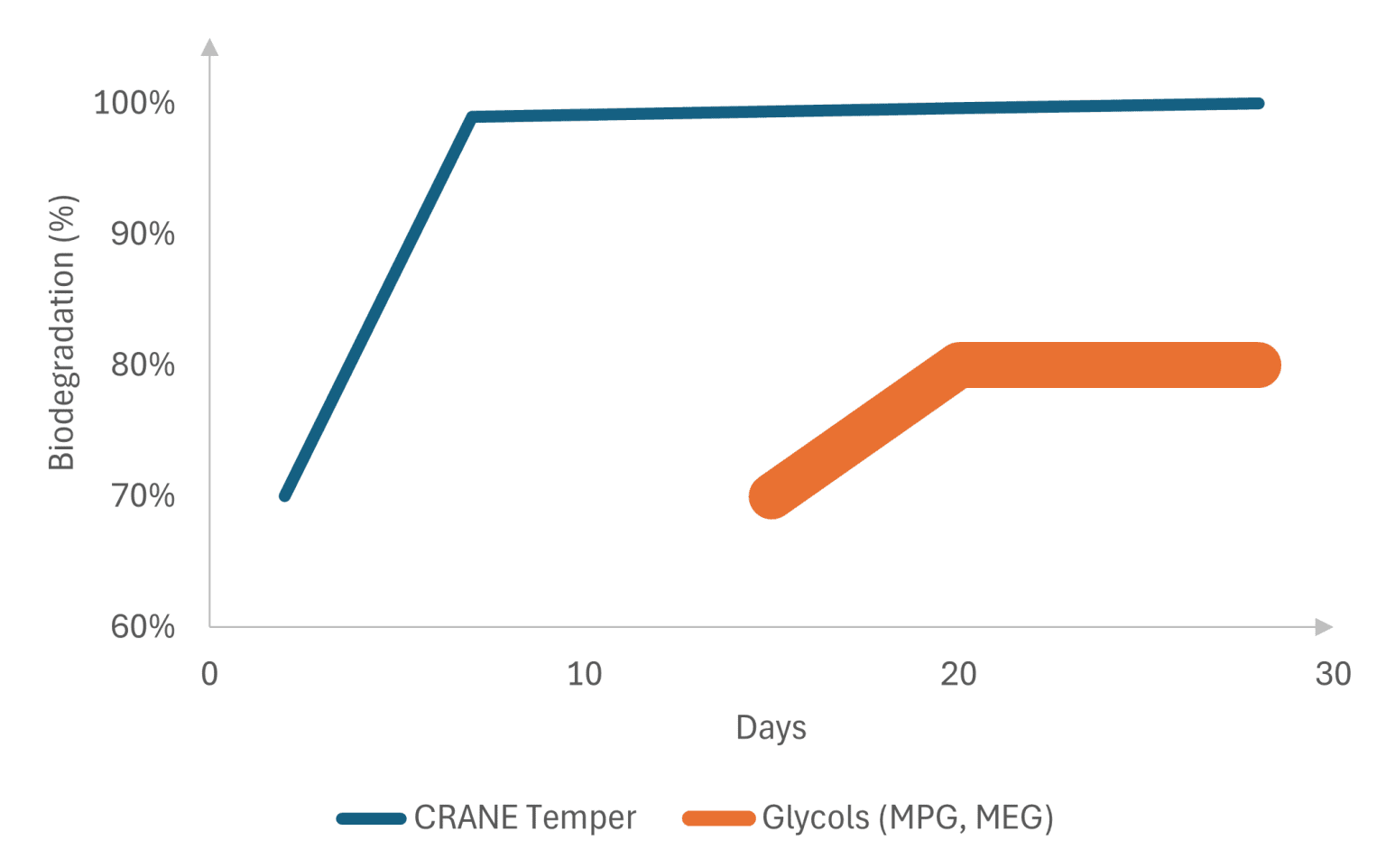

Environment

CRANE Temper is readily biodegradable, nontoxic and non-flammable and does not contain nitrites, borates, phosphates, molybdates or silicates.

The freezing point depression substances in CRANE Temper contains mainly potassium acetate, which is used as food preservative and is more environmentally friendly than many of its counterparts. The properties of potassium acetate ensure it is less corrosive, has a lower toxicity level to fish, mammals and vegetation, meaning environmental impact is minimal.

| Nontoxic to mammals

LD50 (oral, rat) > 5000mg/kg |

Microtox

Not acute toxic |

| Non-toxic to aquatic animals

LC50/96h > 10 000 mg/L |

Readily biodegradable

OECD 301A: 100 % after 28 days |

| Do not bio-accumulate |

Packaging

CRANE Temper is supplied in the following packaging, as well as bulk deliveries for larger volumes;

- 25L blue canister made of PE with sealed cap, the canister’s weight is 1,2kg.

- 208L blue barrel made of PE, with a sealed cap, the barrel’s weight is 9kg.

- 1000 L non-translucent IBC, the IBC weight is 70kg.

Request Product Information

References

Latest News

Trade Affiliations